The gluing system of Mylar aluminum tape laminating machine is mainly composed of four parts: glue tank, rubber roller, doctor blade and anilox roller. Among them, the anilox roller is the core component of the gluing system, which is responsible for evenly transferring a certain amount of glue to the plastic film.

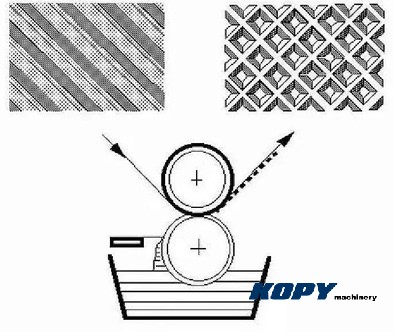

On the surface of the anilox roller, there are many small concave holes with the same shape, which are generally called "inking holes". . The ink wells are generally carved along the direction of 45° to the axis, and the partition wall between the ink wells is called "net wall", and the area of the net wall is related to the shape of the ink hole.

Several common shapes of ink wells include: quadrangular pyramid, quadrangular truss, hexagonal truss, trapezoidal oblique cross-section, and additional channel ink wells. The opening and depth of the ink well have a considerable influence on the glue transfer performance of the ink well. The larger the opening and the shallower the depth, the better the glue transfer; otherwise, the worse the glue transfer. Among the several shapes of ink holes mentioned above, the hexagonal truss-shaped ink hole has a larger opening, so its ink holding and ink release performance is better. Therefore, this shape of ink is often used in engraving anilox rollers. hole.

The number of lines of the anilox roller refers to the number of ink holes per unit length on the surface of the anilox roller, and it is also one of the important parameters of the anilox roller. It also has a very important influence on the glue transfer performance of the anilox roller. Generally speaking, the higher the number of lines of the anilox roller, the smaller the amount of adhesive transfer, and vice versa.

1. Anilox roller scraper angle

The angle between the scraper and the contact tangent of the anilox roll is generally between 25 degrees and 30 degrees. If the angle is too large, the scraper is almost against the anilox roller, and the surface of the anilox roller is not smooth. When it runs at a high speed, it will cause vibration or jump of the elastic scraper blade, causing the solution to be bounced up, resulting in coating The amount of cloth is not uniform, causing a problem of large variation in the amount of coating. In addition, too large an angle can easily damage the scraper blade.

2. The sharpness of the anilox roller scraper

The sharpness of the scraper mainly depends on the angle of blade wear and the purity of the solution and the quality of the knife. If it is a new knife, the appropriate sharpness of the knife should be such that it can effectively scrape off the adhesive liquid layer on the anilox roller without producing a knife wire. The moderate sharpness of the knife can effectively scrape off the solution layer, so as to obtain a uniform coating amount, otherwise, the difference in coating amount will become larger.

3. The flatness of the anilox roller scraper

The flatness of the scraper means that there is no warping deformation, and the coating amount is uniform, otherwise the difference in coating amount will become larger. The flatness of the scraper depends on the method of installing the scraper. Of course, it may also be related to foreign objects stuck in the slot of the knife holder or on the blade and lining. Therefore, when installing the knife, the lining should be wiped clean, and then a new knife should be placed behind the lining. into the slot. The screw on the back of the knife should be tightened from the middle of the blade first, and then gradually tightened to both sides, and both sides should be tightened by rolling. In order to prevent the blade from warping, the screw should be tightened two or three times. While screwing the screw, take a piece of cloth to clamp the blade and the lining, and pull it firmly to one side, so that the resulting knife is relatively smooth. In order to ensure that the coating amount difference is within the standard range.

Contact: Mr. Carlos

Phone: +86 18638794084

Tel: +86 13673680478

Email: kopymachinery@gmail.com

Add: No.5 Hehuan Street, Gaoxin Dist., 450001, Zhengzhou, China.