Battery aluminum foil is used as a current collector for lithium-ion batteries. Typically, the lithium-ion battery industry uses rolled aluminum foil as the positive electrode current collector.

Rolled foils vary in thickness from 10 to 50 microns. The commonly used pure aluminum foil for lithium batteries has various alloy grades such as 1060, 1050, 1145, and 1235, and has states such as -O, H14, -H24, -H22, and -H18.

Technical requirements for battery aluminum foil:

1. The surface of the aluminum foil is uniform in color and luster, clean, and flat in shape, without obvious roll marks, pitting, pinholes, and corrosion marks;

2. There are no rolling defects such as creases, mottled spots, and bright lines on the surface of the aluminum foil;

For the first two requirements, in addition to the production factors of the aluminum foil rolling mill, in slitting process the surface of each drive roller of the battery aluminum foil slitting machine is also required to be clean and smooth, so as to avoid damage to the aluminum foil surface .

3. There is no color difference on the surface of the aluminum foil;

4. There is no oil on the surface, no serious oily smell, and no oil spots visible;

5. Surface tension, dyne pen test is not less than 32 dyne;

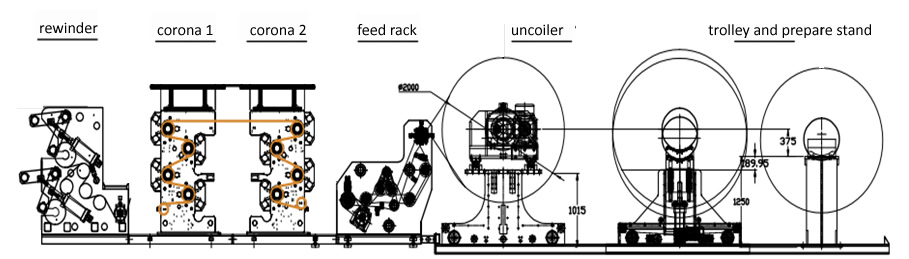

In view of the fifth requirement, the tension control of the battery aluminum foil slitting machine are extremely critical. Our aluminum foil slitting machine adopts active transmission of all rollers, and the whole machine is controlled by servo drive to meet the above tension requirements of battery aluminum foil.

The latest research in the lithium-ion battery industry has found that the charge-discharge characteristics of the battery can be improved by etching and roughening the surface of the aluminum (Al) alloy foil used as the positive electrode collector of the lithium-ion rechargeable battery. Compared with the aluminum foil without surface treatment, the binding force between the surface-roughened aluminum foil and the active material is significantly improved. Surface roughening is generally achieved by corona treatment to aluminum foil. Our aluminum foil slitter can be equipped with a corona machine between the feeding and slitting main machine to corona the aluminum foil while slitting, so as to directly produce aluminum foil rolls for batteries.

Contact: Mr. Carlos

Phone: +86 18638794084

Tel: +86 13673680478

Email: kopymachinery@gmail.com

Add: No.5 Hehuan Street, Gaoxin Dist., 450001, Zhengzhou, China.