Cause

The thickness tolerance of the composite film roll is relatively large

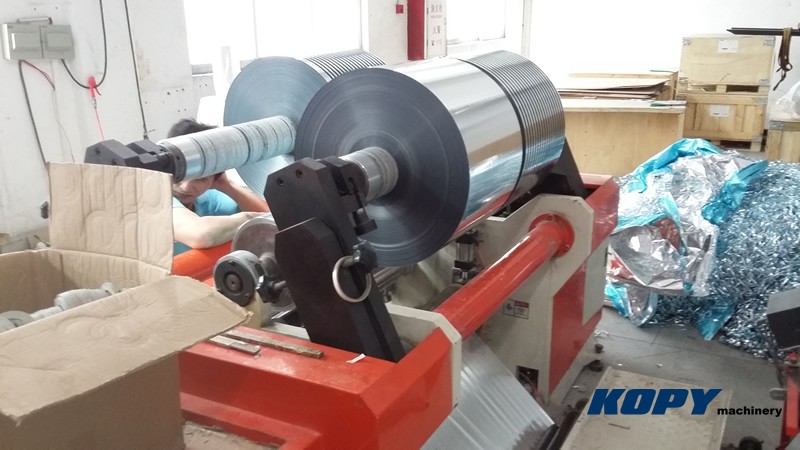

Winding appears curling

The surface friction coefficient of the composite film roll is small, and lateral sliding occurs

Cutting speed is too fast

The parallelism of the winding shaft and the contact roller deviates

Acceleration and deceleration process is too fast

Improvements:

Adjust the tension, increase the contact pressure, and reduce the amount of air involved

Improve Laminated Film Roll Quality

Adjust the knife or replace the blade

Reduce slitting speed especially when slitting slippery material

Reduce or increase speed slower

Contact: Mr. Carlos

Phone: +86 18638794084

Tel: +86 13673680478

Email: kopymachinery@gmail.com

Add: No.5 Hehuan Street, Gaoxin Dist., 450001, Zhengzhou, China.