I. Before start the machine, adjust the position limit sensor to proper position. Adjust the air pressure to 8. Then Turn on power switch, the blade base will move to the right end automatically in 20 seconds. Then check the power indicator light, manual operating switches, each page in touch screen and water sprayer, and confirm everything is normal. Then press down the chuck switch, the chuck and axis tail support will close. Then press the “EFFECT SWORD” switch, the blade base will go back to 0 position (the “adjusting blade” key in screen “cutting setup” page should be green lighted). Make sure the position limit plate contact the position limit sensor, otherwise the blade base does not move. When the position limit plate contact the position limit sensor, the light on the sensor will light.

II. Adjust the blade position according to the material roll diameter. Then press “MANUAL FEEDING” switch and hold, till the blade edge just cut the PE tube into 0.1 – 0.2mm depth. If the cutting depth to the PE tube cannot reach an ideal condition by operating “MANUAL DEEDING”, you may press the “cutting blade ahead bit” or “cutting blade back bit” on touch screen to adjust the cutting depth.

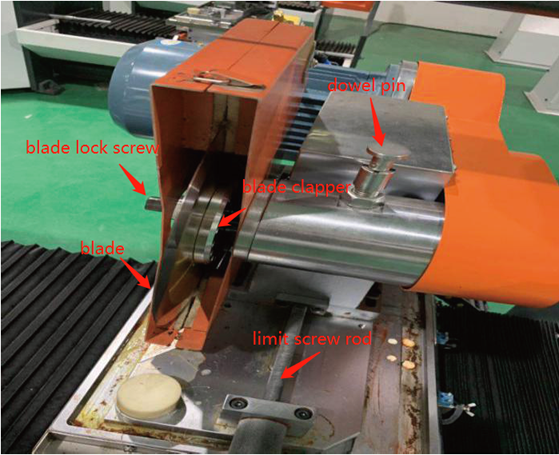

III. Fasten the limit screw rod to make the screw rod press the limit block, then turn half round reversely, then fasten the nut on the screw rod. Finally press “CONFIRM”, the blade return to the cutting start position.

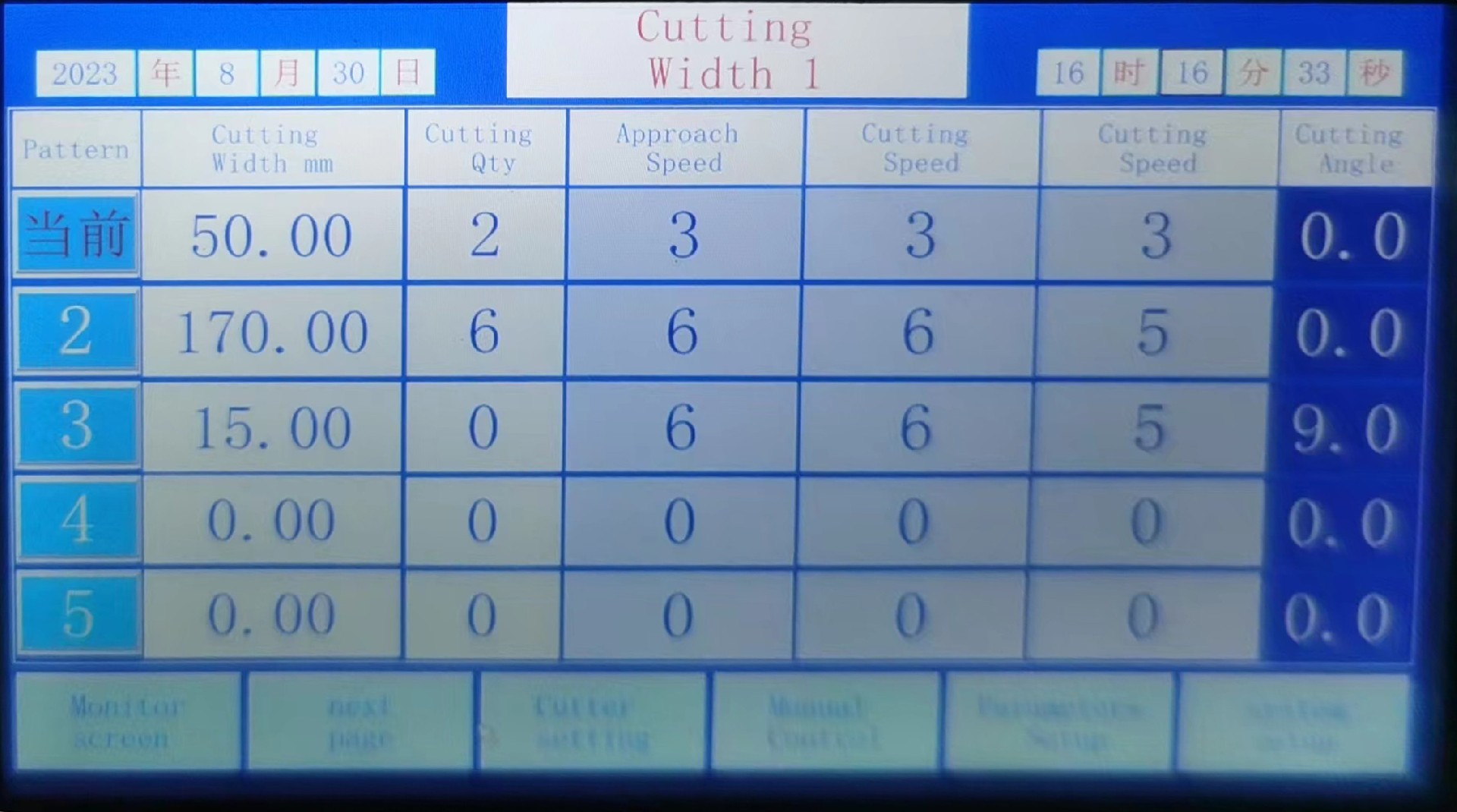

IV. Set the parameters in touch screen. Enter the width setting page, click the serial number 1 column, and set the cutting data of the first cut. Most of the times, the first cut is to trim the edge of the material roll, so the width of the first cut can be any width, the cutting quantity is set to 1, and the angle is set to 0 or a positive angle, depending on whether the shape of the round blade edge is monoclinic or double bevel. Set the appropriate value for the feed speed of each segment. Next, click on the serial number 2 column to set the product slitting width, and then set the product slitting quantity. The calculation of slitting quantity is: total width of material to be cut ÷ slitting width = slitting quantity (take an integer), please note that for the last cut if you want to trim the edge in the opposite direction, then you need to reduce the number of cuts in column No. 2 by one cut, then click on column No. 3, set the quantity to 1, the cutting width is the same as the previous cut, the cutting angle is opposite to the first cut, and the width setting is completed.

V. Short press the motor start on the cross switch, adjust the rotation speed of the circular knife and the spindle speed respectively according to the material cutting requirements, then load the material, manually move the blade to the first cut cutting position, and press the automatic cutting switch to enter the automatic cutting process. After the complete roll of material is cut, the blade automatically returns to the first cut position, and the entire cutting operation is completed in this cycle.

Contact: Mr. Carlos

Phone: +86 18638794084

Tel: +86 13673680478

Email: kopymachinery@gmail.com

Add: No.5 Hehuan Street, Gaoxin Dist., 450001, Zhengzhou, China.