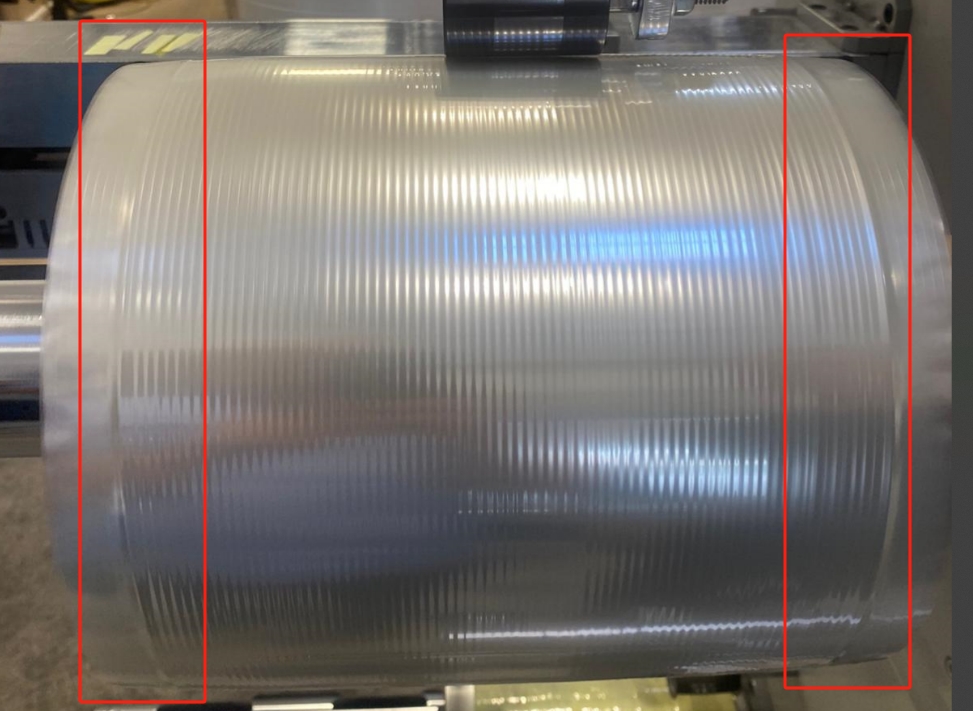

Some times when rewind the thin films especially elastic material on spooling machine, it's easy to got two tubercles on two side of the finish spool as showed in below image. This situation will obviously lower the appearance and even the users may refuse to accept the goods. So, how this tubercles happen and how to prevent it?

When do spooling, the tape moves traversely on the winding core when winding shaft rotating. At the two edges of the spool the overlaps of each layer film in a width area are less than the other area in the middle. When the spool diameter gets bigger after thousands of rounds winding, the two edges area is absolutely softer than other area. Additionally if the film gets elongated in winding process, the tubercles at two edges will appear.

To solve this problem, we can set the spooling machine to wind some more circles on the two sides of spool in every traverse round. Additionally, if the film is thin and elastic, we can reduce the unwinding tension and winding tension to protect it from being elongated.

Contact: Mr. Carlos

Phone: +86 18638794084

Tel: +86 13673680478

Email: kopymachinery@gmail.com

Add: No.5 Hehuan Street, Gaoxin Dist., 450001, Zhengzhou, China.