Have you ever been confused about the concept of surface winding, center winding and center surface winding when you were trying to select a slitting machine from internet. Here I will explain you with 3 images.

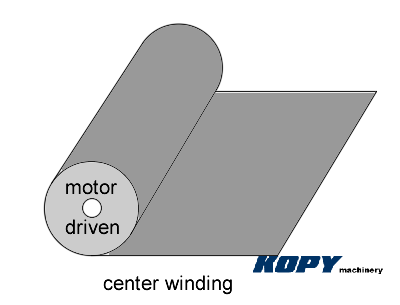

Center winding means the winding shaft is driven by motor and can rotate independently.

By this means, the winding force comes from the torque of the center winding shaft. Hence, it causes big tension to the tape. If the tape is soft and elastic material, this winding method is not suitable.

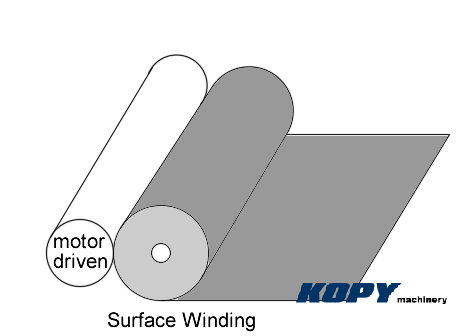

Surface winding means the winding shaft does not rotate by itself, but be squeezed and driven by a motor-driving roller which is next to it.

In this way, the winding does not produce big tension to the tape. While if the tape material is hard and heavy, the driving roller need to press the winding roll tightly to drive it rotating. And also it may damage the surface of the tape.

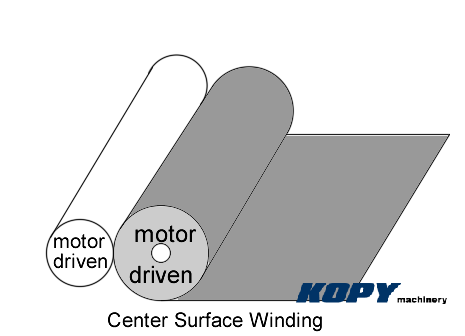

Center surface winding means the winding shaft is driven by motor and rotates indenpendently and addtionally there is a motor driven roller next to it and help feeding the tape onto the winding roll.

Generally, this winding method meets more flexible slitting request. Only the machine building cost will be higher than the first two mentioned methods.

Contact: Mr. Carlos

Phone: +86 18638794084

Tel: +86 13673680478

Email: kopymachinery@gmail.com

Add: No.5 Hehuan Street, Gaoxin Dist., 450001, Zhengzhou, China.